It’s pretty exciting when you’re in the right place at the right time. That is exactly how biotechnology major Alex Williams '20 felt when he attended the first BioHackNH, held this month at the University of New Hampshire at Manchester.

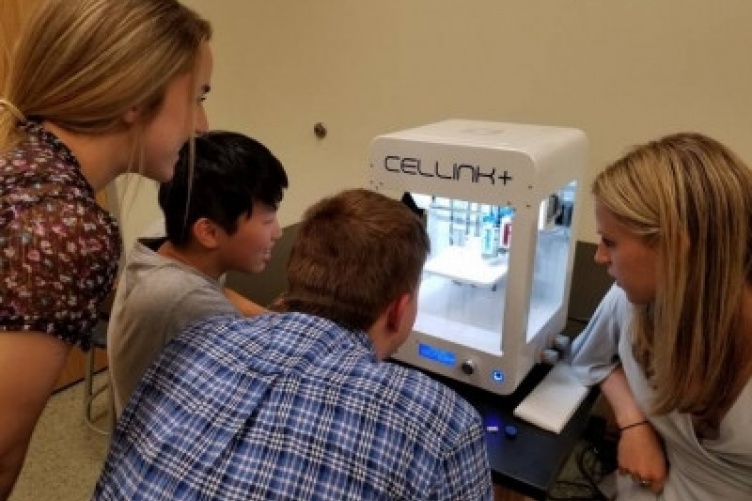

Hosted by UNH Manchester, the Advanced Regenerative Manufacturing Institute (ARMI) and CELLINK, BioHackNH brought together college students from around the state to learn more about regenerative manufacturing using CELLINK bioprinters.

“This regenerative manufacturing industry is popping up all around us,” Williams said. “I feel like I’m in the right place at the right time and am taking every opportunity I can.”

So, what exactly is regenerative manufacturing, and what makes it so exciting? In simple terms, it’s the engineering and growing of tissues and organs in labs. This innovative new industry has the potential to change how we approach healthcare and treat disease.

“The impact it could have on society is meaningful,” said Colby Jordan, executive director of Hitchcock Management, who had been at UNH Manchester earlier in the week to practice printing ears and noses. “Think about just the potential for burn victims.”

This potential is what drives Williams and fellow biotech major Lizz Maurais '19, who talked about the high number of people on kidney transplant waiting lists each year.

“This could mean a lot for the world, even if it’s 20 or 30 years down the road,” Maurais said. “We want to try to make a dent in those numbers.”

During BioHackNH, students were broken up into teams and given guidance by Elisabeth Rebholz and Sierra Flanagan of CELLINK, an innovative biotechnology company and the first bioink company in the world. Students spent the first day coding, 3D modeling, testing materials, practicing with the printers and troubleshooting within teams. On the second day they were challenged to print a vascular system. Some students came in with no coding experience.

“The whole point is to do it and mess up,” coached Mary Stewart, director of education and workforce development at ARMI. “I didn’t have coding experience, but I took what already existed for a nose and tried to put a wart on it. My wart ended up in the inside of the nose, so I knew I had to fix something.”

Students were willing to do just that. According to one student’s written reflection, one of the highlights was “learning how the code directed the printer. I never knew anything about coding or how the printers work. Now I do.”

As I lurked around the room the first day, I also felt I was in the right place at the right time. Listening to the students was an amazing experience. Students who were initially intimidated later told me they were excited to be making progress. Another shared her realization that she needs to be more aware of coding and her ideas for improving her academic program. Others made observations about the different viscosities of the materials they were testing.

Manchester Community College student Mario Pecoraro perhaps captured the feeling of the event best.

“I love this,” Pecoraro said. “It lights up my brain.”