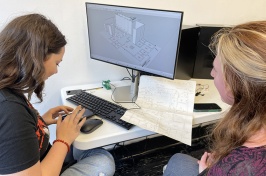

UNH graduate student Christopher Rogers ’17G (left) and statistics lecturer Phil Ramsey at Kingsbury Hall

In 2014, there were about 70,000 motor vehicle accidents in New Hampshire.

Christopher Rogers ’17G explains that hidden in that number, which includes everything from minor fender-benders to fatal crashes, are hundreds of small clues — about the age of drivers, types of injuries, time of day and so on — that, with the right analysis, state officials say could help reduce accident totals each year.

Rogers looked for those clues earlier this spring as part of a new collaboration between UNH and the New Hampshire Department of Safety. Rogers and other student interns are using Lean Six Sigma principles to help make roadways safer.

“Lean Six Sigma is about continuous improvement,” Rogers says. Lean principles focus on reducing waste, while Six Sigma provides tools and analyses for process improvement. Manufacturers, corporations and organizations large and small — including UNH and a number of state agencies — use the methods.

“We have a great relationship with the university and the New Hampshire Lean Network,” says Roberta Emmons, a business systems analyst with the Department of Safety. “There’s quite a lot of collaboration between the university and the state.”

Rogers, a graduate student in the mathematics and statistics department, analyzed statewide traffic data for the Department of Safety earlier this year. Using the data set, Rogers looked for “relationships between things such as age and type of injury or between time of day and age” using techniques he learned in courses with statistics lecturer Phil Ramsey.

Rogers examined accident data to find relationships between dozens of variables and how those variables affect traffic safety.

According to Ramsey, Rogers’ collaboration with the Department of Safety is one of a series of opportunities for students to learn Lean Six Sigma methods both in and out of the classroom.

“Many students coming out of universities have no introduction to any of these methods, but they’re likely to work in environments where they’re commonly used,” says Ramsey, who has two decades of experience with Lean Six Sigma. Ramsey began offering a course focused on the methods last fall.

Along with in-classroom instruction, Ramsey’s course also gives undergraduate and graduate students the chance to become a Six Sigma-certified green belt, which is the basic level of certification. The engineers and scientists who developed Six Sigma at Motorola in the 1980s were “karate fanatics,” Ramsey says. To become certified, students can sign up for a one-credit internship that involves working on a data analysis project with an outside organization.

In addition to Six Sigma certification, Ramsey says, it gives students important practical experience. In the last year, three math department students worked with New Hampshire state agencies.

Working with the Department of Safety, Rogers had the chance to look at data for relationships between dozens of variables and how those variables affect traffic safety. Many of the results were “intuitive,” he says: Younger drivers are more likely to get into accidents, while older drivers are less likely.

“It’s something everyone is aware of, but it’s helpful to have a test that shows that,” he says.

He also examined the quality of the data. While federal law requires states to collect and report data on fatal accidents, it does not require states to collect or analyze data on nonfatal crashes.

“He told us all we could know about who was crashing on roadways in the state in 2015,” Emmons says. “He really helped give us the whole picture at once, as opposed to seeing it in pieces as we’re asked questions.”

“Having a solid background in Lean Six Sigma goes a long way to being workforce-ready, especially if students have gotten to work on a real project.”

Emmons adds that Rogers’ analysis helps point state police and other agencies in the right direction for setting policies and patrolling roadways. “Our next phase is taking that crash data and overlaying it with our ticketing data and see … if we ticket in the right spaces, can we deter crash occurrence and severity?”

In fact, Rogers is already working on that analysis as part of his master’s thesis. And once he graduates, he plans on consulting with businesses and other government agencies to “utilize techniques such as Lean Six Sigma to really solve problems.”

For his part, Ramsey hopes to see the internship program expand to include graduate students in other departments as well as collaborations with other state agencies and private businesses.

“Having a solid background in Lean Six Sigma goes a long way to being workforce-ready, especially if students have gotten to work on a real project,” he says.

Interested in graduate school at UNH? Find out more here.

-

Written By:

Larry Clow '12G | UNH Cooperative Extension