One of the challenges many college students face when they land their first job after graduation is how to put the skills they've learned to use in a real world setting. Students in the Mechanical Engineering Technology program at the University of New Hampshire at Manchester are getting an opportunity to make that transition a little early – and under the eye of a seasoned mentor – through the university’s internship program.

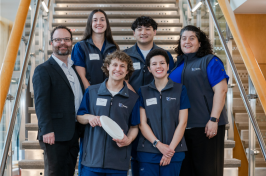

Jeffrey Deming and Alex Roy are two Mechanical Engineering Technology majors set to graduate in May who have been embedded in a Manchester-area company for their internship. The two are working on a project at Manchester based Velcro, overseen by mentor Sam Kirshman, a tooling engineer with about 40 years of engineering experience.

“They have a chance to implement everything they've learned, including past experiences and capabilities,” said Kirshman. “They show very good initiative. They are both very bright guys.”

“It’s been a really great learning experience dealing with the wide variety of people you need to work with. It’s not a one-man show in any industry,” said Deming.

Deming and Roy were tasked with analyzing an existing system at Velcro to find a way to reduce processing time and increase output by 50 percent or more. Simply put, they needed to take a Velcro machine and engineer an adjustment that makes it work faster. First they reviewed designs and machine drawings to get ideas. Next they came up with a few ideas and presented them to Kirshman. He said their proposals were similar to those Velcro engineers had already identified.

“It showed us their train of thought was correct,” said Kirshman.

The students then moved on to fabricating the improvement. Once complete, the students will formally present their idea to their UNH Manchester advisor as part of their senior project. In the engineering program, students working on their senior project are typically embedded in a company as an intern with an assigned company mentor. Their project includes developing a solution to a problem and creating a manufacturable prototype or mechanical improvement for an existing system that incorporates the solution. That could include using engineering skills like designing, programming and form factoring.

The senior project aims to give students experience they may not always get in the classroom – building something that will be used in a real life situation. Engineering internships are not only beneficial to the students looking to gain practical experience. They also help Manchester-area firms find young, talented future employees, said Kirshman.

“As the company experiences growth and after years of being in business, there are many people here who get to be older and retire,” said Kirshman. “One of the things interns allow us to do is not lose all those capabilities when leaving by having them transfer their knowledge to a younger person. There’s a value in continuity of capability and knowledge that’s pretty important.”

“As the company continues growing, we are always looking for talent. It’s not always easy to find,” he added. “The internship is a way to see how they perform.”

Deming said he’s had to put his engineering skills and knowledge to work plenty at Velcro, but that he’s also relied on skills he’s learned at UNH Manchester that aren't typically associated with an engineering degree.

“Most of what we've had to call upon is our communication skills and technical writing skills,” said Deming.

Before his Velcro internship, and even more now, Deming said he’s understood how important strong communication skills are to the job.

“You can have a great idea but it’s worthless if you can’t tell anyone about it,” he said. “It muddies the whole system when you’re trying to express something if no one can pick up what you’re putting down.”

-

Written By:

Beth LaMontagne Hall | Freelancer