Composting is an important practice used in sustainable agriculture and gardening. Disposing of food scraps through composting creates fertilizer that can be used in home gardens, in greenhouses, and on farms. Food scraps aren’t the only material that is valuable for creating compost; animal waste, human waste, and items such as wood shavings and paper plates and napkins are also decomposable ingredients. From an environmental point of view, composting is an important practice that prevents these materials from entering landfills where they decompose at a much slower rate than when put directly into compost piles. Composting also can be a valuable source of heat. When the microorganisms that are abundant in these organic materials perform decomposition, their metabolism produces a significant amount of heat in the compost pile. As an environmental sciences: ecosystems major at the University of New Hampshire (UNH), I was intrigued by the importance of composting and how it can benefit our society.

The author, Dena Hoffman.

In research at UNH, composting plays an important role in studying sustainability. I wanted to explore these research opportunities for my honors thesis. I approached Dr. John D. Aber, my former professor for Intro to Environmental Sciences, who pointed me in the direction of a project he was working on that involved composting, greenhouses, and creating a model in Microsoft Excel from those two components. I’d never made a model before, so I decided to take this opportunity to learn something I believed would be a valuable addition to my skill set. The research I conducted for my honors thesis applied a model to the UNH campus to consider the possibility of capturing heat generated from aerated static composting piles and using it as a renewable energy source to heat our greenhouses.

There are multiple farms and greenhouses on the UNH campus. These greenhouses are used for research purposes as well as teaching purposes, all while growing crops such as brussels sprouts, tomatoes, eggplants, green peppers, and okra. Many of these crops are used in the dining halls or at the on-campus restaurant, the Dairy Bar. Heating greenhouses for year-round crop production in the New England climate can be cost-prohibitive. It is important to consider that we have the potential at UNH to create a source of sustainable energy that fuels the production of food we eat on campus. I believe this is the next step toward a more sustainable campus and hope that my research will provide a positive example for those in the commercial agricultural industry as well.

Composting Basics

A variety of components can go into compost, but the main requirements are an oxygen source, a carbon source, a nitrogen source, microorganisms, and a material that can decompose. Microorganisms require an oxygen source to perform aerobic decomposition. Oxygen can be provided by turning compost piles manually or by drawing air down through the static piles. Carbon is the energy source for the microorganisms; some examples of carbon sources are sawdust and wood shavings. Nitrogen is necessary for the microorganisms to produce proteins and build cell walls, and this nutrient comes from animal waste. With adequate oxygen, carbon, and nitrogen, the microorganisms will grow rapidly in the compost (Risse and Faucette 2017).

An aerated static composting pile at the Organic Dairy Research Farm in Lee, New Hampshire.

During the decomposition process, the microorganisms in the pile excrete enzymes that break down the compostable materials into smaller molecules, which they can then take up directly and consume. Heat is generated by the microorganisms’ metabolism and can get as high as 150 degrees Fahrenheit (Smith and Aber 2017). The final product of composting is a green fertilizer that improves the soil’s water retention and provides available forms of nutrients needed to grow healthy, nutrient-rich crops.

Comparing Composting Systems

There are two different types of composting systems to consider: traditional, manually turned piles and aerated static piles. At UNH’s Kingman Farm, each windrow, or pile of compost, is about 200 to 300 feet long and comprises food waste from the dining halls at UNH and equine waste from the equine facilities. It takes a considerable amount of effort to turn these composting piles, which are established directly in the field. Kingman Farm workers use a machine called a turner that is about 10 feet wide and 5 feet tall. The turner is pulled by a 108-horsepower tractor of a good stature and moves at 0.2 miles/hour. Each pile is turned every two to three weeks, and it takes a full year for a compost pile to be ready for use. During the last couple of months of the yearlong process, the compost sits and cures without being turned. Once the compost is ready, farmworkers spread it on the research fields at Kingman Farm.

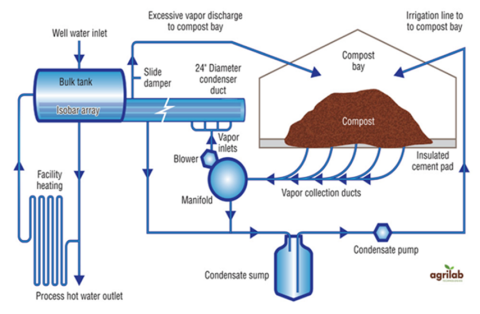

In contrast to Kingman Farm’s composting system, UNH’s Organic Dairy Research Farm uses aerated static composting piles that consist only of animal manure from the cows and wood shavings used as bedding. The main difference between the two composting systems is that the aerated static composting piles do not get turned. The Organic Dairy Farm piles are kept in a large shed that protects the compost from weather events such as rain or snow. In the shed, the compost sits on concrete. These piles remain in the same place, and rather than getting oxygen through turning the pile, air is pulled down through the pile and then through drilled pipes in the floor by a fan attached to those pipes so that the microorganisms are provided with their needed oxygen source (see Figure 1).

Figure 1. This illustration shows how heat is collected from an aerated static composting pile.

Aerated static composting piles reach a much higher temperature than traditional turned piles, which completes the composting process more quickly. These piles can be ready for spreading in as little as three weeks, although the material is often held for longer periods of time to maximize total heat gain. This compost is then spread over the fields at the Organic Dairy Farm to supplement the pasture grasses.

Temperatures generated from static composting piles are high enough to become useful for heating structures like buildings. Dr. Aber and I chose to consider aerated static composting piles in our model because of the large heat capture capabilities. With my research I hope to promote the feasibility of using aerated static composting piles to heat greenhouses on the UNH campus.

UNH Greenhouses

To create a model for using composting as a heat source for greenhouses, I needed to understand the different roles and components of greenhouses at UNH. New Hampshire experiences high seasonality, which means that there are very defined seasons: autumn, winter, spring, and summer. Seasonality can limit the amount of time that crops can be grown, because the end of fall, winter, and the beginning of spring are such difficult times to grow crops. High-tunnel greenhouses are plastic enclosures that help extend the growing season by creating an environment that is warm enough to grow crops throughout the year. The structure of a high tunnel, such as those on the main campus of UNH, ranges from a simple greenhouse frame with roll-up plastic curtains and a layer of polycarbonate to a more elaborate setup with supplemental heating, an irrigation system, roof vents, and the ability to be moved to different locations.

There are four sets of greenhouses at UNH: the Fairchild Dairy Farm greenhouses on the edge of the main campus, the Kingman Farm greenhouses two miles away from campus, the Woodman Farm greenhouses at the northwest edge of campus, and the MacFarlane Research Greenhouses relatively close to the center of campus. The MacFarlane Research Greenhouses are traditional glass houses used for various research projects. These greenhouses are more structurally sound than the high tunnels because of the simple fact that glass is heavier than plastic. These greenhouses are also much larger than the high tunnels at Fairchild, Kingman, and Woodman, and require more energy to heat. I did not include these greenhouses in creating and applying my model; rather, I focused on high-tunnel greenhouses.

The greenhouses at Woodman Farm and the Fairchild Dairy Farm are simple high-tunnel greenhouses. Several of these high tunnels receive supplemental heat during the colder months. At Fairchild, students run an Instagram page called @farmtoyounh to showcase what they are growing and learning there for their Sustainable Agriculture and Food Systems 680 class. The three high-tunnel greenhouses at Kingman Farm are more complex, with aquaponic systems inside of them. There, aquaponics researcher Todd Guerdat grows crops such as lettuce while maintaining a population of fish that provide nutrient-rich water and waste that directly fertilize the crop soil.

Kingman Farm. Photo credit: UNH Drone/Communications and Public Affairs.

The high-tunnel greenhouses at Kingman require an external source for heat as well as having a set of tanks and pipes to get water to the plants and the fish tanks. The Kingman greenhouses use heat from September 15 to May 15. Todd Guerdat said heating the three greenhouses over the course of a year takes about 232 million BTUs. To put this into perspective, an average house like my family’s 1,296-square-foot home takes about 9 million BTUs to heat from September to May, which is significantly less than the Kingman Farm greenhouses (We Love Fire 2020). Because of the high energy cost of operating the Kingman Farm greenhouses, we chose to incorporate these specific greenhouses into our model.

Reducing the amount of nonrenewable energy that it takes to heat the greenhouses at UNH would be a positive action because it would represent a movement toward more sustainable sources of heat. This would also mean a reduction in total cost, because it would remove the need to buy heat from an outside company. A reduction that helps the environment and your wallet is a win-win situation.

Creating the Modeling Program

When creating the Microsoft Excel model of the greenhouse energy balance, we had to take into consideration a multitude of variables when it came to the New England climate and the ability of greenhouses to retain heat. Throughout the fall semester of 2018, Emily Dutton (a December 2018 graduate) and I combed through greenhouse- and energy-related literature to put together the puzzle that would become the model. It took a couple of months of reading through different pieces about how greenhouses are built and why they lose heat energy throughout the day to allow us to simplify complex mathematical equations that contained the factors we needed, such as the rate of heat transfer or the air exchange parameter. Dr. Aber and I designed our model based on the dimensions of the Kingman Farm greenhouse. However, the model can be manipulated to represent any size greenhouse.

In early 2019, Dr. Aber and I began to build the Excel model by plugging in the dimensions of the greenhouse for reference. Dr. Aber received data from Kingman Farm about the daily and hourly temperatures in January 2014, a notably cold winter. By using a colder winter in our model, we could illustrate that it is still feasible to heat a greenhouse with composting even in more extreme temperatures. For our model we set our indoor greenhouse temperature at 60 degrees Fahrenheit, but the model can be manipulated to whatever indoor greenhouse temperature the user wants.

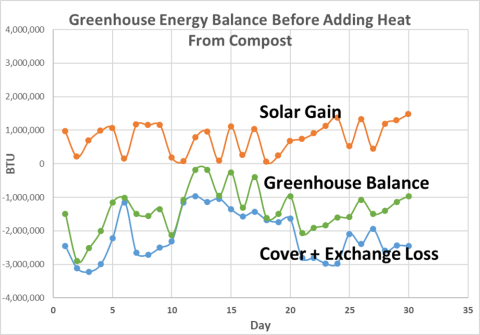

Figure 2: This graph shows that the energy balance of the greenhouse is negative due to a large cover and exchange loss and little solar gain to supplement the greenhouse’s energy needs.

The variables involved in our model included greenhouse constants such as length, width, sidewall height, peak height, surface area of the cover, floor area, and internal volume. Variables also included cover constants such as type (we used polycarbonate in our Excel model), rate of heat transfer, light transmissivity, air exchange parameter, and sun angle effect. Our Operational Goal variable was the internal temperature. Other variables included meteorological data such as outside temperature, the temperature difference between outside and inside, solar radiation, and wind speed.

The data for the constant values, including the greenhouse dimensions and those variables related to its cover type, were obtained from our own measurements of the Kingman greenhouses and by consulting previous literature on the subject. The data for the other variables were obtained from daily meteorological measurements made at Kingman Farm by the UNH Established Program to Stimulate Competitive Research, which we accessed from the Data Discovery Center. I then determined the temperature differences between the indoors and the outdoors each day for the whole month of January 2014. From there, Dr. Aber and I created equations based on all of these variables to determine the energy going into the

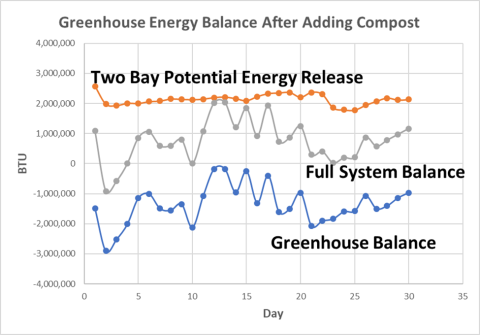

Figure 3: This graph shows that when we add heat capture from two aerated static composting piles, the full system balance (the greenhouse plus the compost piles) is largely positive.

greenhouse, the energy lost because of the polycarbonate covering of the greenhouse, and the energy lost because of air exchange. This resulted in what we called the hourly balance, or the amount of energy that could be present in the greenhouse at each hour. I compiled this data into a daily balance of heat measured in BTUs per day.

Next, Dr. Aber entered into our Excel model the information about heat generated from the aerated static compost piles at the Organic Dairy Research Farm, based on the research of graduate student Matt Smith. He totaled the amount of energy coming from two composting piles and then added the greenhouse daily heat balance to the total heat generated by the composting piles to find the overall system balance. With this data, we produced graphs illustrating the energy difference between a greenhouse with and without heat captured from aerated static composting (see Figures 2 and 3). The graphs displayed great potential for using compost piles as a heat source for greenhouses, and I presented this research at the UNH Undergraduate Research Conference (URC) in April 2019.

Taking the Model Further

The findings I presented at the URC used sample data from actual aerated static piles at the Organic Dairy Research Farm for the model. However, I wanted to take this further and determine the efficacy of additional aerated static piles to heat UNH greenhouses. To determine if it is possible to generate enough heat from static compost piles to heat all of the high-tunnel greenhouses on campus, we first needed to determine how much compost UNH can create.

We received data from the UNH equine facilities, the Organic Dairy Research Farm, and UNH Dining to understand how much material could potentially go into aerated static composting piles. The equine facilities at UNH house a substantial number of horses (close to forty), which equates to a substantial amount of horse manure. According to Brenda Hess-McAskill from the equine facilities, the average amount of manure and shavings mixture produced is 60 tons per month. This means that in one year, around 720 tons of manure and shavings mixture are created.

At the Organic Dairy Research Farm, 68 tons of cow waste are produced per month, every month of the year, by the cows living on the farm (Smith 2015). This results in a total of 816 tons per calendar year. UNH Dining is associated with three dining halls that produce copious amounts of food waste per day. In a study led by dietetics interns in February 2016, food waste was collected at Holloway Commons, Philbrook Dining Hall, and Stillings Dining Hall, for a total of 1,226 pounds of post-consumer food waste (plate waste) across the dining hall facilities over one day (L’Italien 2016). That number does not include waste from food prep. Another campus report estimates that UNH Dining produces 274 tons of food waste per year (Composting Team 2016). The town of Durham is another possible source for compost material, since it produces around 375 tons of food waste in one calendar year. Based on all of these possible sources, UNH can generate 2,186 tons of compost material per year.

To test our model and determine the feasibility of heating the high-tunnel greenhouses, next we needed to determine how much energy it takes to heat these greenhouses from September to May. Todd Guerdat explained that the high tunnels need 4,000 therms of propane to run. To put a “therm” into perspective, one therm is equivalent to 100,000 BTUs. One full year for all seven greenhouses (Kingman, Fairchild, and Woodman) needs an average of 400,000,000 BTUs. Using all of the possible compost sources described above, 2,186 tons of compost per year could generate a total of 3,060,400,000 BTUs. If you divide the total number by the required 400,000,000 BTUs needed to heat a single high tunnel in one year, you get the number 7.65. This means we could heat seven high-tunnel greenhouses and a little more for a full year by using the heat generated by two new aerated static piles. If we used only the UNH Dining food waste and the waste from the equine facilities, which is a total of 995 tons per year, we could heat three greenhouses, such as one at Kingman and two at Fairchild, because the compost could generate 1,393,000,000 BTUs in one year.

Conclusion

Based on my model, I believe that UNH can take on the project of using aerated static composting piles to heat their greenhouses, which would further promote the excellence of our sustainability as a campus. In future research, I think it would be important to record more data from different aerated static piles regarding their heat generation as it relates to their size. Another possible route is taking meteorological data from different cities around the country to see how that influences the model and the feasibility of combining composting and greenhouses elsewhere. I hope that UNH will consider the possibility of this project seriously and start working toward making it a reality. I believe Dr. Aber would be a great person to head this project and provide the research needed for the work. I truly think that a system created like this could further green energy’s momentum and continue to show UNH’s standard of sustainability.

Doing a project of this magnitude taught me a lot about dedication, problem solving, and how much potential there is to practice composting as a society. This research project also helped to solidify my desire to work in the environmental sciences, pursuing a graduate degree or employment as an environmental consultant. Making choices that better our environment is something we all need to work toward. I believe that we can all contribute to sustainability in our own little ways, and for me that means sharing this research to educate others about the potential of aerated static composting piles to produce renewable energy.

First and foremost, I would like to thank Dr. Aber for taking me on as his mentee and for guiding me every step of the way. He was a great influence on my time at UNH, and I could not be more thankful for him. Next, I would like to thank Evan Ford, Todd Guerdat, and Brenda Hess-McAskill for letting me ask them questions or interview them in person to further develop this project. I want to thank Emily Dutton for being a part of the team back in fall 2018 and for helping kick-start the research. I am also very grateful to my family and friends for their encouragement and endless support. Lastly, I want to thank the United States Department of Agriculture, Sustainable Agriculture Research and Education Program, and the NH Agricultural Experiment Station at UNH for funding my project.

References

Composting Team. “Zero Waste Initiative—Composting Team—Final Report.” University of New Hampshire. May 2016.

L’Italien, Rochelle. “Post-Consumer Dining Hall Food Waste Summary Results over Eight Hour Collection Intervals (Spring, 2016).” www.unh.edu/dining, University of New Hampshire Dining Services, Feb. 2016.

Risse, Mark, and Britt Faucette. “Food Waste Composting: Institutional and Industrial Applications.” UGA Extension, University of Georgia, 30 Jan. 2017.

Smith, Matthew M. Unpublished graduate research. 2015.

Smith, Matthew M., and John D. Aber. “Energy Recovery from Commercial-Scale Composting as a Novel Waste Management Strategy.” Applied Energy, Elsevier, 11 Nov. 2017.

We Love Fire. 2020. “How Many BTUs Do I Need for My Room or House?” welovefire.com/btu-calculator/.

Author and Mentor Bios

Dena Hoffman, from Hudson, New Hampshire, graduated from the University of New Hampshire in December 2019 with a bachelor of science degree in environmental sciences: ecosystems. She conducted her research as part of her honors thesis for the University Honors Program. Her research journey began in the fall of 2018 when she asked Dr. John Aber if he knew of any research opportunities and he invited her to join his work on composting. Dena’s learning from the research process included the useful skill of being creative in finding information. She explains, “I never thought that I would interview a farm manager to learn about composting rather than just looking up information on a database.” Dena was particularly satisfied by presenting her research at UNH’s 2019 Undergraduate Research Conference. “If given the opportunity I would do it all again,” she says. She decided to publish with Inquiry to learn about the editing process and because she’s proud of the work she’s done with Dr. Aber and thought Inquiry would be a great way to show it to the world. She looks forward to a future helping to preserve our environment and educating people about doing their part. She is open to the many possibilities in this field, from teaching at the college level to working in water quality or natural disaster relief. Whatever lies ahead, Dena knows that the skills she gained through this project will help her in the future.

John D. Aber is a professor in the Department of Natural Resources and the Environment. He began teaching at the University of New Hampshire in 1987. Dr. Aber’s areas of teaching and research specialization include environmental science; forest responses to global change, such as climate and pollution; and agroecosystems and sustainable agriculture. A grant through the USDA Sustainable Agriculture Research and Education (SARE) program allowed concepts developed studying forest ecosystems to be applied to agricultural systems. Through his time at UNH, many undergraduates have benefited from research mentorship by Dr. Aber. He says that it is always satisfying to see students gain real research experience, and that Dena’s project was especially interesting because of the direct application to sustainability and agricultural research right here at UNH. He also shared that it was impressive to see Dena, who had no real agricultural experience, tackle this kind of applied agricultural and sustainability project. Dena is the first Inquiry author Dr. Aber has mentored. He wholeheartedly believes in the importance of researchers writing for a general audience and says, “Translating science for general audiences is especially important now with so many in public life misusing or ignoring science. Making science accessible and applicable and convincing is a noble calling.”

Copyright 2020, Dena Hoffman