|

UV INTENSITY SENSOR: The UV intensity sensor is a photosensitive detector that measures UV intensity at a specific location inside the reactor. The following photos show examples of the UV sensor. UV

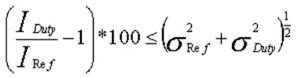

sensor on reactor (Photo 1) The UV intensity is recommended to be monitored continuously, but the recommended recording frequency for UV intensity is every four hours (USEPA, 2003). UV intensity sensors can monitor the intensity either by a dry or wet sensor. For a dry sensor, intensity is measured by placing the sensor on a monitoring window. For the wet sensor, the sensor is placed directly into the water in the reactor. Over time fouling can occur on wet sensors and monitoring windows. Fouling can be removed by cleaning by chemicals or physical wiping. Each UV intensity sensor will be built according to each manufacturer’s individual design. Components of the intensity sensor include the photodetector, amplifier, and other optical features, such as monitoring windows and light pipes. The number of UV intensity sensors can vary. Some reactors may only need one sensor to monitor multiple lamps while other reactors will have a sensor for every lamp. The USEPA's draft Ultraviolet Disinfection Guidance Manual (2003) recommends that MP lamps have a sensor for each lamp. LP and LPHO lamps may only have one sensor along the lamp for each bank of lamps. The location of the intensity sensor is also critical. The sensor should be located where the lowest lamp output occurs. In addition to the on-line or duty sensor, there needs to be a reference sensor. The reference sensor is used to verify that the on-line sensor is properly calibrated. The reference sensor should be stored properly when not in use and only used for calibration of the on-line sensor. The USEPA's draft Ultraviolet Disinfection Guidance Manual (2003) recommends the following steps for checking the duty sensor calibration:

5. Install another duty sensor if the above equation does not hold true, and send the other sensor to the UV manufacturer to be recalibrated. Calibration checks for the on-line sensor should be performed monthly using the reference sensor. The reference sensor should be calibrated on a yearly basis by a qualified party. |

||||||||

|

|