|

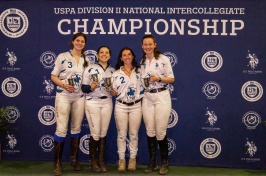

For their senior project, Vincent Lyon, (from left), Britta Moore, and Garrett Cassidy fabricated a bicycled-powered washing machine that can clean a load of clothes in 30 minutes using only six gallons of water. |

In rural areas of India, China, and other developing nations, dirt is ubiquitous. So are bicycles, used as a major form of transportation. But washing machines? They’re not so plentiful, so cleaning clothing is done by hand, an arduous, time-consuming task.

Until, perhaps, now. Three UNH mechanical engineering students have created a bicycle-powered washing machine that cleans clothes with just six gallons of water, 30 minutes of easy pedaling, and no electricity.

“In countries where washing machines aren’t available, this would free you up to do more interesting things,” says Britta Moore ’12, who designed and created the washing machine as a senior capstone project with Garrett Cassidy ’12 and Vincent Lyon ’12. The trio was inspired by a TED Talk speaker who addressed the life-changing impact of washing machines in rural areas.

“The purpose of this product is to bridge the gap between convenience and sustainability,” the students write in their research poster. If the students are successful, their invention could bring a whole new meaning to the concept of “spin cycle.”

The washing machine consists of a 30-gallon plastic drum (the prototype is from a car wash) drilled full of holes and placed inside a 50-gallon metal drum. Clothes, soap, and a scant three gallons of water go into the inner drum, which agitates and spins via gearing that links the user’s bicycle to the double-drum system. Washing, rinsing, and spin-drying each take ten minutes, a cycle comparable in time to a standard electric washing machine. With an additional three gallons of rinse water, the machine uses significantly less water than the 27-plus gallons a top-loading electric washer uses.

“And if you’re using biodegradable soap, you could use the gray water to water crops,” Lyon says.

Among the design’s most important features, the creators say, is the ubiquity of its materials in developing nations. “You could build this in a third-world country with minimal tools,” Lyon says, noting that a drill and basic welding are all that’s required to assemble the washer out of scrap materials and a few basic items from a hardware store. Alternately, all materials could be packed and shipped inside the larger drum.

And, in an improvement over other such machines, the team assures that no bicycles are harmed in the cleaning of undies. The UNH team made it a design priority to power the washer with a bicycle that could be removed and ridden away.

“In areas where the bicycle is the primary mode of transportation, you don’t want to sacrifice it,” Lyon says.

Guided by advisor Brad Kinsey, associate professor of mechanical engineering, the team spent the fall semester planning and designing their washing machine; their knowledge of getting clothes clean now far exceeds that of the average college student. This spring, they built and tested their prototype, testing the strength of materials, determining optimal gear ratio to spin clothes efficiently without overtiring the “operator,” and comparing cleaning abilities with varying amounts of water and soap. They even subjected a white shirt to the “mustard test” of detergent advertising fame.

The team members – all graduates of ConVal High School in Peterborough, N.H. – are cyclists themselves. Moore, from Temple, and Cassidy, from Hancock, are regular commuters, and Lyon plans to bike the 70-plus miles home to Antrim after graduation. They’re also active in energy and environmental issues on campus.

All three students will return to UNH in the fall – Cassidy and Lyon to begin graduate school, and Moore to finish up her bachelor’s degree – and will work toward bringing the bicycle-powered washer to developing nations, possibly finding a business partner and entering it into UNH’s Holloway Prize Innovation-to-Market competition. In the meantime, they’ll continue to perfect the design in the most practical way: by using it to wash their clothes.

Originally published by:

UNH Today

Written by Beth Potier, UNH Media Relations. Photo by Mike Ross, UNH Photographic Services.